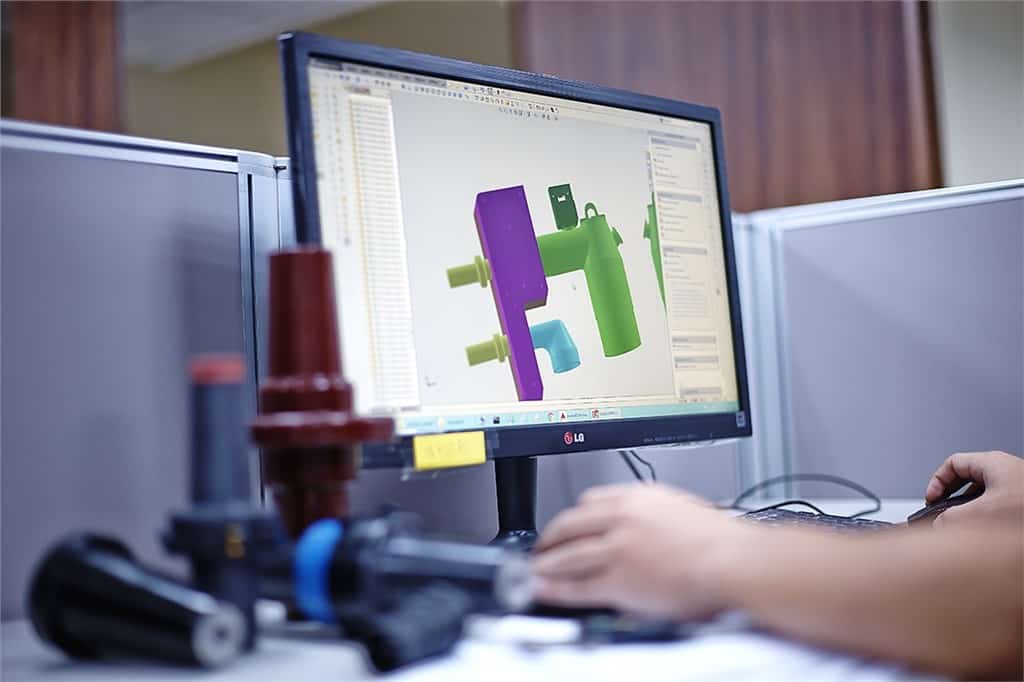

You want reliable, cost-effective, and high-performance solutions for your industry. We've got you covered.

Chardon can assist you in manufacturing durable cable connecting systems and products that will help you reduce operational and replacement costs, while minimizing grid outages.